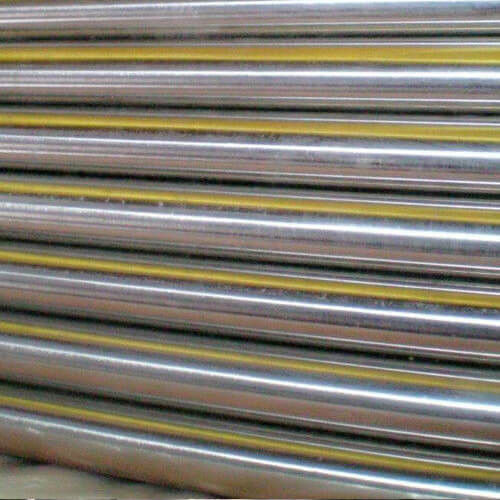

ASME BPE standard food grade high Purity Stainless Steel 316L Sanitary Tubing

- Place of Origin

- Wenzhou, China

- Certification:

- ASME BPE / 3A / ISO9001

- Model Number:

- CX-SPT-011

- Minimum Order Quantity:

- 1 piece

- Prices:

- Contact us for the best quote

- Packaging Details:

- Plywooden case

- Delivery Time:

- 7~30 days EXW.

- Payment Terms:

- L/C, D/A, D/P, T/T, Western Union, MoneyGram

- Supply Ability:

- 10,000pcs per month

Detailed Product Description

| Material: | TP316L | Specification: | ASME BPE / ASTM A270 S2 |

|---|---|---|---|

| Size: | 1/2'' X 24'' | Length: | 6 Meters Or According To Customers' Requirements |

| Tube Finish: | ID / OD Polished | ||

| High Light: | sanitary stainless pipe , stainless steel sanitary tube | ||

ASME BPE Sanitary Stainless Steel Pipe , High Purity Stainless Steel Tubing

Features:

CX offers ASME BPE stainless steel sanitary tubing that is manufactured to the stringent ASME BPE and ASTM A270 S2 specifications. This high quality tubing is 100% boroscoped and mechnically polished on both the ID and OD, certified to 20 u-in Ra (0.5um) inner diameter (ID) maximum, and 30 u-in Ra (0.8um) outer diameter (OD) maximum surface roughness. Surface finishes are measured per ASME/ANSI B46.1, with the profilometer reading at 90 degrees to major polish pattern. Our A270-BPE series tubing significantly reduces customer inspection requirements prior to installation by utilizing only the highest quality stainless steel materials. We offers industry leading stainless steel sanitary tubing along with technical expertise and unmatched service. We stock all standard ASME BPE tubings in size 1/2'' - 6'' in 20ft lengths.

Descriptions:

| Item Code: | CX-A270-316L-0050-065-MP-BPE |

| Tube OD.: | 1/2'' |

| Wall: | 16 Gauge (0.065'') |

| Length: | 20' |

| OD Tolerance: | +/-0.005'' / +/-0.13MM |

| WT Tolerance: | +/-10% |

| Length Tolerance: | +1/8'' / +3.18MM |

| Material: | TP316L |

| Standard: | ASME BPE / 3A / ASTM A270 S2 |

| Finish: | 20Ra ID / 32Ra OD |

| Polish: | SF1 / Mechanical Polished |

| Type: | SEAMLESS |

| Certification: | ASME BPE |

| Mill Test Certificate: | EN10204 3.1 |

| Packing: | Sleeved, Ends Capped, Wooden Boxed |

Chemical Compositions:

| Elements | 316L (wt%) |

| C / Max. | 0.035 |

| Mn / Max | 2.00 |

| P / Max | 0.045 |

| S / Max | 0.005 - 0.017 |

| Si / Max | 1.00 |

| Ni | 10.00 - 14.00 |

| Cr | 16.00 - 18.00 |

| Mo | N/A |

| Fe | Bal. |

| Cu | N/A |

| N | N/A |

Mechanical Properties:

| Grade | Tensile Strength (Mpa) |

Yield Strength (Mpa) |

Elongation (%) |

Hardness (HRB) |

| 316L | ≥485 | ≥170 | ≥35 | ≤90 |

Quality Assurance:

CX ASME BPE stainless steel sanitary tubing undergoes a rigorous quality inspection, including destructive and non-destructive examination, at the mill prior to shipment.

1. Chemical Composition: PMI Test

2. Mechanical Properties: Tensile Test, Hardsness Test

3. 100% Eddy Current, Air Under Water Test, Hydrostatic Test

4. Flange Test, Flattening Test, Reverse Flattening Test, Reverse Bending Test.

5. Dimensional Check: OD, WT, Straightness

6. Metallurgical Test

Applications:

Our ASME BPE stainless steel sanitary tubings are applicable to a wide range of manufacturing industries:

1. Food & Beverage

2. Dairy

3. Wine & Brewery

4. Cosmetic

5. Pharmacy

6. Biotechnology